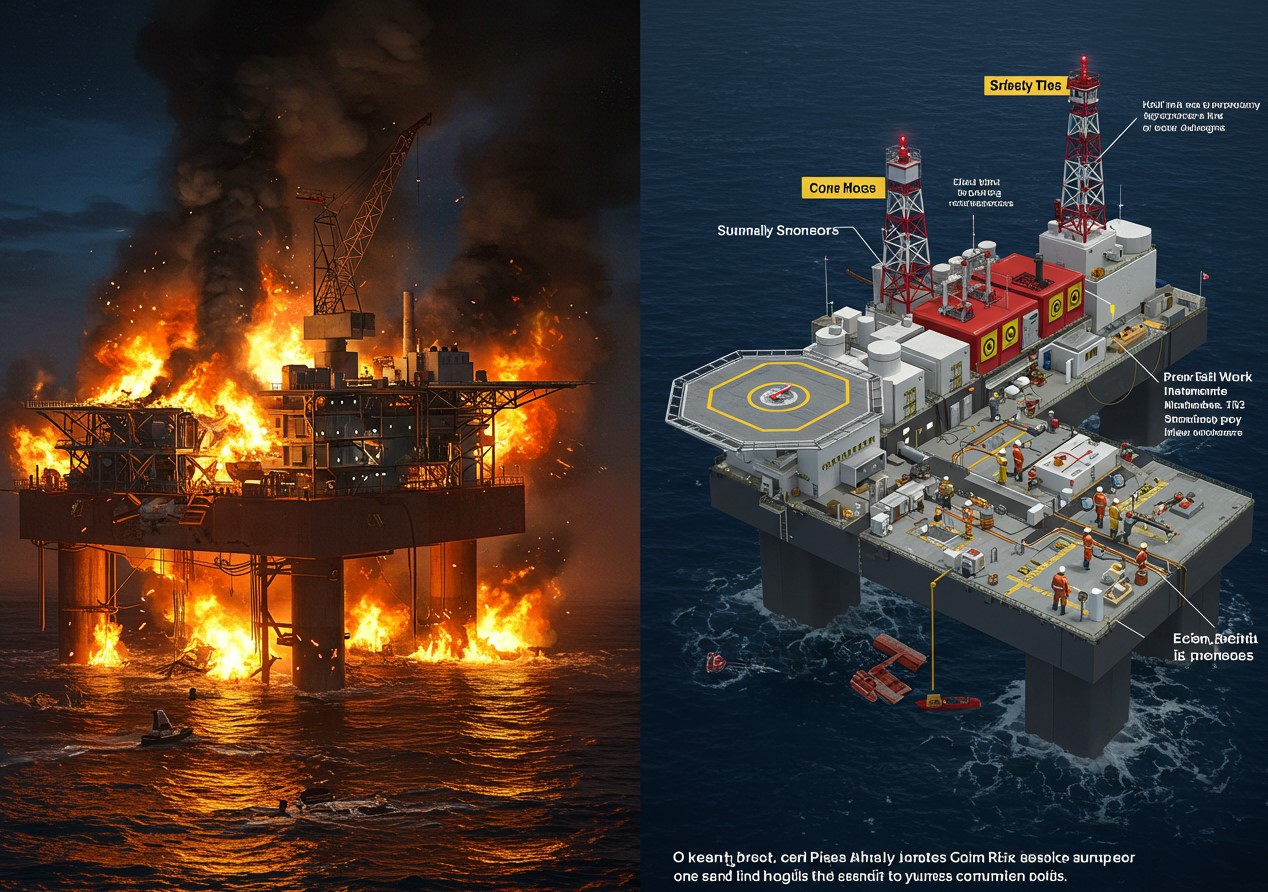

The Piper Alpha disaster (July 6, 1988) remains a turning point in industrial safety history. With 167 fatalities and massive economic losses, this accident on the North Sea oil platform exposed systemic failures in risk management that—tragically—remain relevant today.

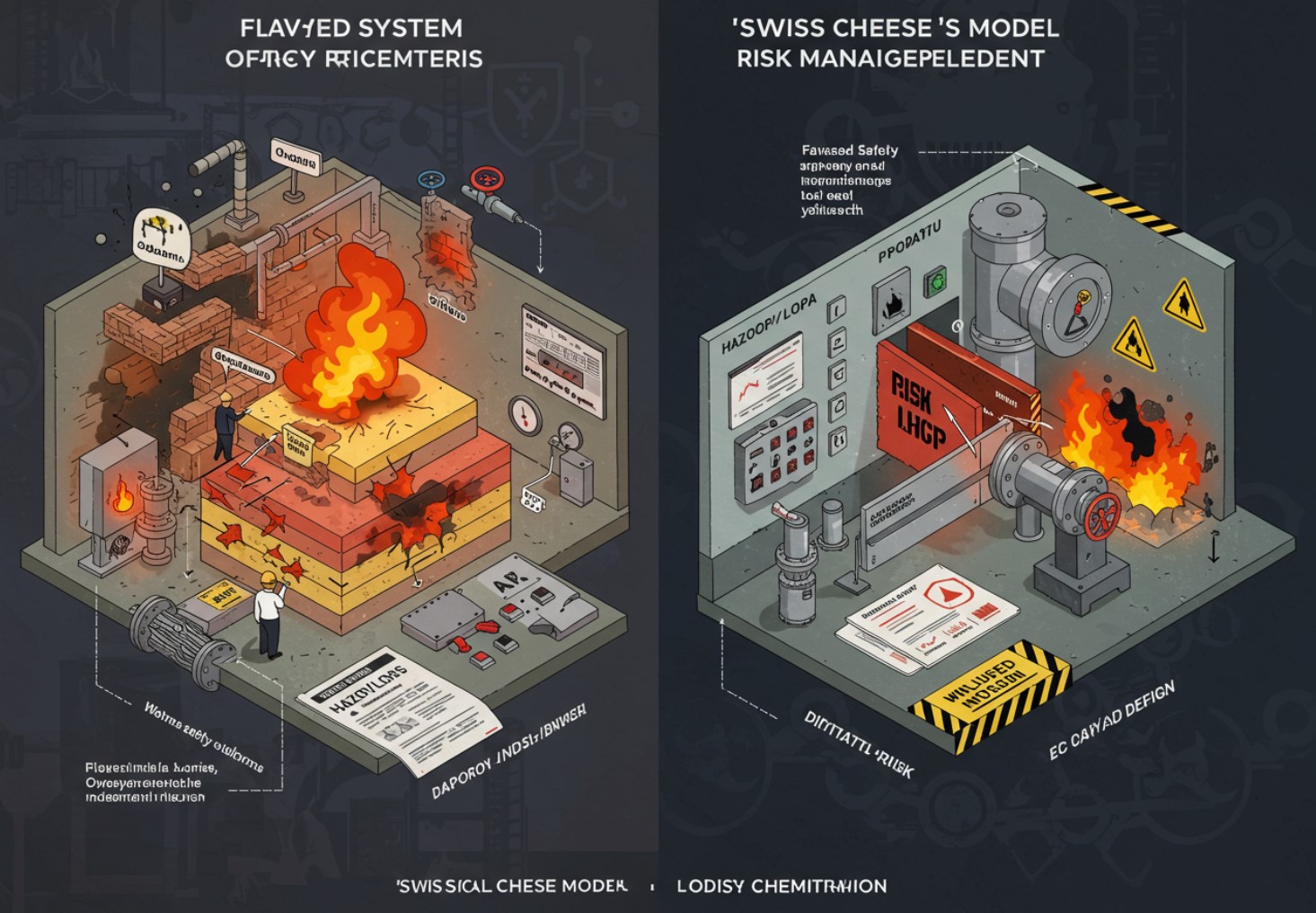

This article, based on Álvaro Conde‘s detailed analysis (CST – CONSERTO S.A.S.), reconstructs the critical events leading to the catastrophe using methodologies like BowTie and failed barrier analysis. Its goal is clear: to transform pain into lessons, identifying principles every industrial organization must internalize to avoid repeating fatal mistakes.

Piper Alpha: Brief Context

Piper Alpha was one of the North Sea’s most productive platforms in the 1980s, originally designed for oil processing but later adapted to handle natural gas. This unrigorously assessed modification was the first link in a chain of failures:

-

Inadequate risk analysis: Explosion scenarios were ignored; only fire risks were considered.

-

Incomplete barriers: Fire-resistant walls were installed, but not blast-proof ones.

-

Fragmented management: Poor work permit systems and communication protocols.

The trigger was a propane gas leak from a poorly secured relief valve during maintenance. What followed was devastating:

-

Initial explosion in Module C (22:00 hrs).

-

Cascade failures:

-

Firewater system manually disabled (to protect divers).

-

Neighboring platforms (Tartan and Claymore) kept pumping fuel into the fire.

-

Structure collapsed after multiple explosions, dragging the living quarters (evacuation zone) into the sea.

-