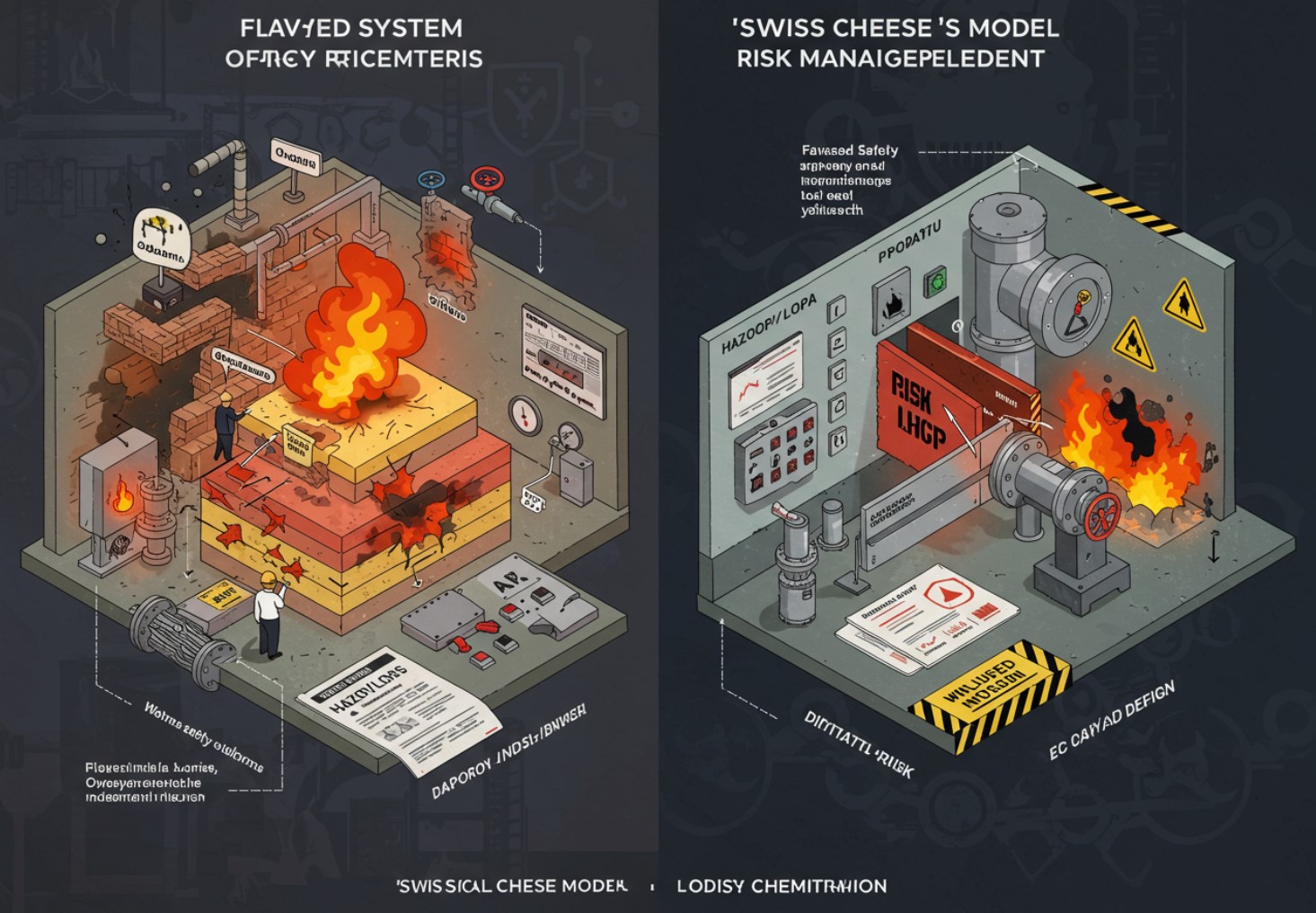

In the field of process safety, the correct identification and classification of protective measures are essential to ensure the integrity of operations, personnel, and the environment. One of the most widely used approaches for risk assessment is Layer of Protection Analysis (LOPA), a semi-quantitative methodology that determines whether implemented controls are sufficient to mitigate high-risk scenarios. However, a recurring challenge in its application is the confusion between safeguards and Independent Protection Layers (IPLs), which can lead to risk underestimation with potentially catastrophic consequences.

This article, based on the work presented by Holman Leonardo Sotelo Rojas at the 10th Latin American Conference on Process Safety (LACPS 2024), explores the key challenges in differentiating these concepts, their impact on risk management, and best practices to avoid critical errors.

Safeguards vs. IPLs: Why Is the Distinction Crucial?

Safeguards are generic control measures that can prevent or mitigate an undesired event. These include alarms, operating procedures, relief valves, among others. However, not all meet the rigorous criteria to be considered Independent Protection Layers (IPLs), which must be:

-

Independent: Must not rely on other systems or the basic process control layer.

-

Specific: Designed to address a particular risk.

-

Auditable: Their performance must be verifiable through testing and documentation.

-

Reliable: Must have a low Probability of Failure on Demand (PFD).

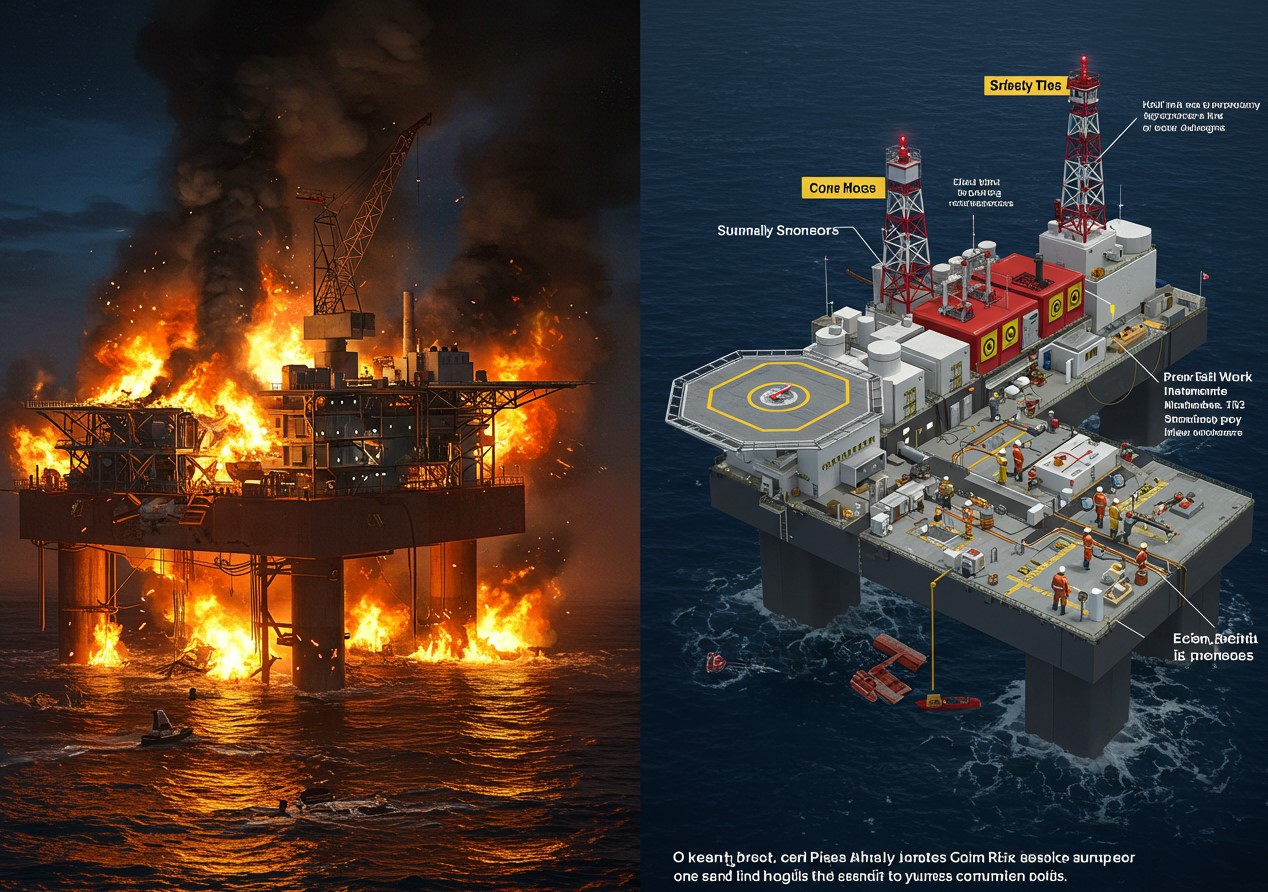

Confusing these concepts can create a false sense of security. For example, in the Buncefield disaster (UK, 2005), the failure of a level sensor and a safety switch (which did not fully meet IPL criteria) resulted in a massive spill and a fire causing millions in losses.

Methodology and Best Practices

The paper emphasizes the importance of rigorous LOPA analysis, where each protective measure must be individually evaluated through key questions:

-

Is the safeguard independent of the initiating event and other layers?

-

Can its effectiveness be audited and verified?

-

Is it designed to act against a specific scenario?

-

Does it meet the required reliability (e.g., PFD ≤ 1×10⁻²)?

If any answer is negative, the measure does not qualify as an IPL and should not be counted toward risk reduction.

Conclusion

The conceptual clarity between safeguards and IPLs is not merely academic but an operational necessity. As the author states, «All IPLs are safeguards, but not all safeguards are IPLs.» Their correct identification prevents protection gaps and ensures risks are managed within tolerable limits.

To explore these criteria further, case studies, and practical examples, review the full document, which includes references to standards like IEC 61511 and lessons from historical incidents.